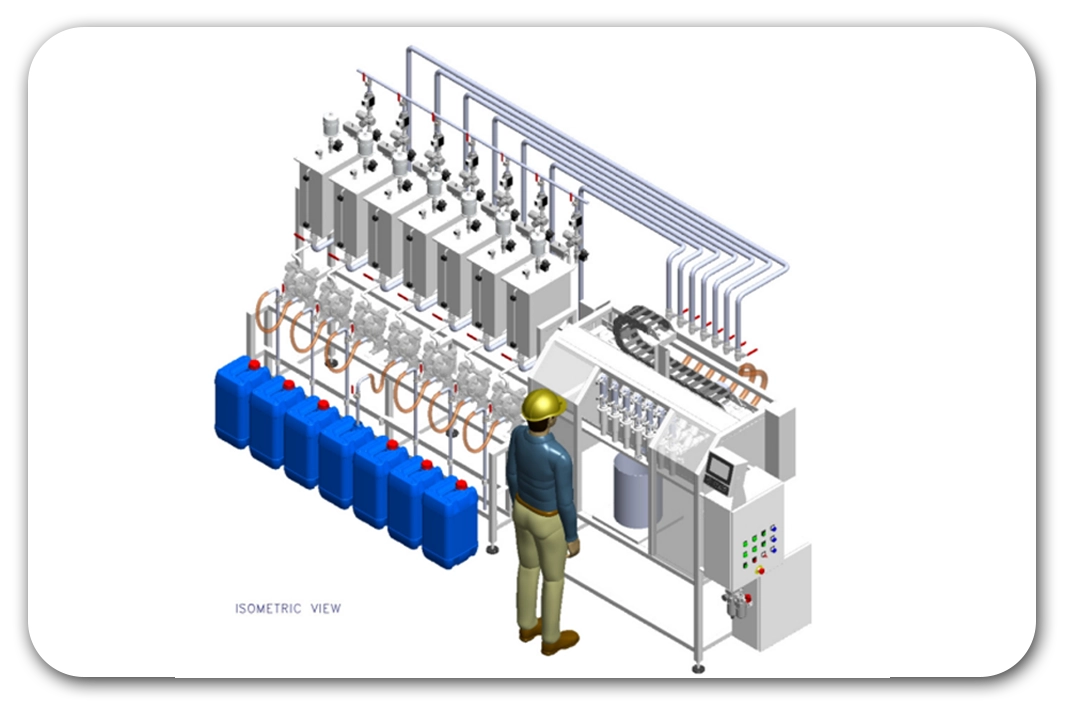

LIQUID FILLING MACHINE

Suitable for packing liquid: Water, Oil, Herbicide, liquid chemicals

Specification

- Speed: 3-5 barrel per head per minute

- Control and display data by Indicator: 920i from America

- Manual barrel loading system with corrosion protection equipment

- Weighing by 1 load cell

- Synchronize with convey and storage system for packing, helping to decrease production damage

- Able to save data to computer and print weighing report

- Main body: Stainless steel 304

- Drain system included

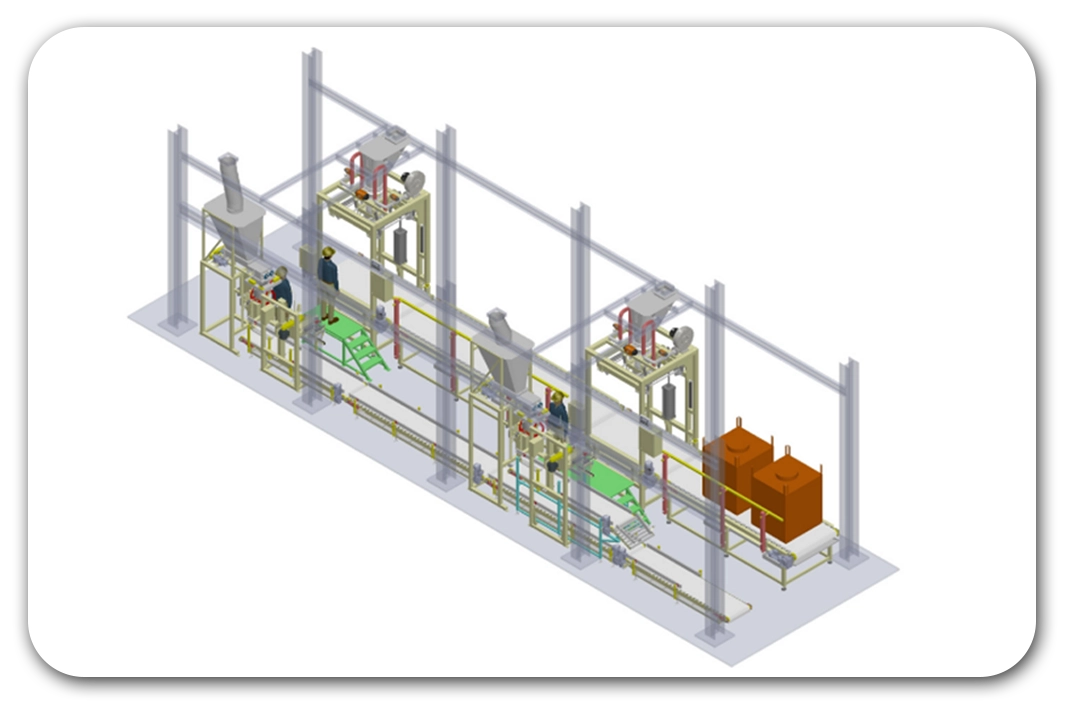

JUMBO BAG

Suitable for packing: Rice, Sugar, Tapioca flour, Plastics pellets, Resin pellets, Soda ash, Pet food, other seed/ grain like products

Specification

- Capacity: 500-2,000 kg

- Readability: 0.2 kg

- Accuracy: +/-0.5 to +/-1.5 kg

- Speed: 4-12 bags/ hour (Depend on products)

- Electronic screen controller

- Weighing by 4 load cells

- Main body: color sprayed steel

- Product Approaching/ tank part: Stainless steel 304

- Power source: 380 VAC 3 phase, electric power: 3.5 kW

Additional equipment

- Out feed Conveyor, QC scale, Buzzer Alarm, Inventory Weighing System, etc.

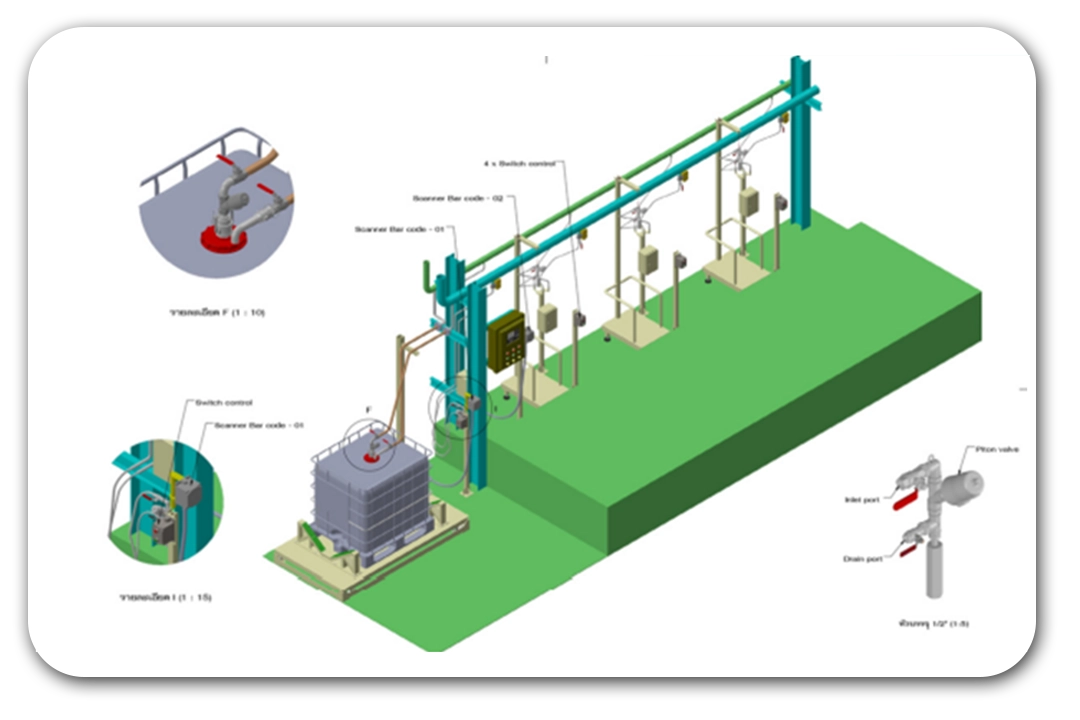

GROSS WEIGHT

Suitable for packing: Fertilizer, Rice, Pet food, Etc.

Specification

- Packing size: 5-50 kg

- Speed: 300 bags/ hour (depend on products)

- Electronic screen controller

- Install and attach with storage barrel

- Main body: color sprayed steel; Product Approaching/ tank part: Stainless steel

- (Option: Stainless steel for all parts)

- Flow control with air cylinder (double acting type)

- Weighing by 2 load cells

Additional equipment

- Data storage program, Printer, Sewing machine, Stand, Conveyor

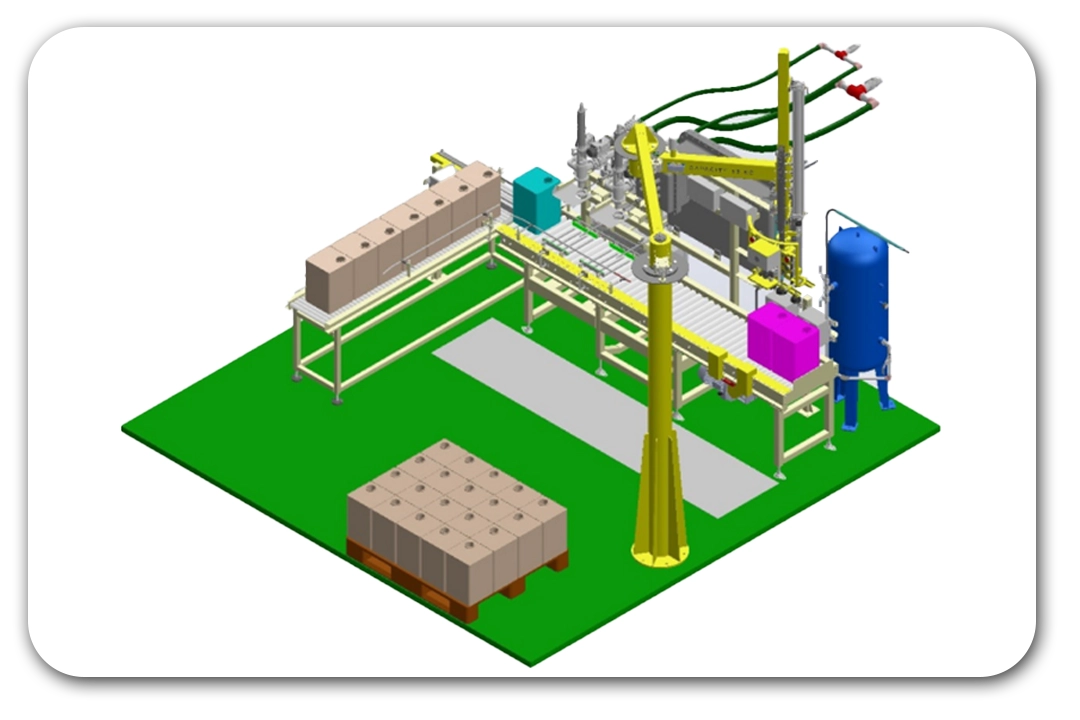

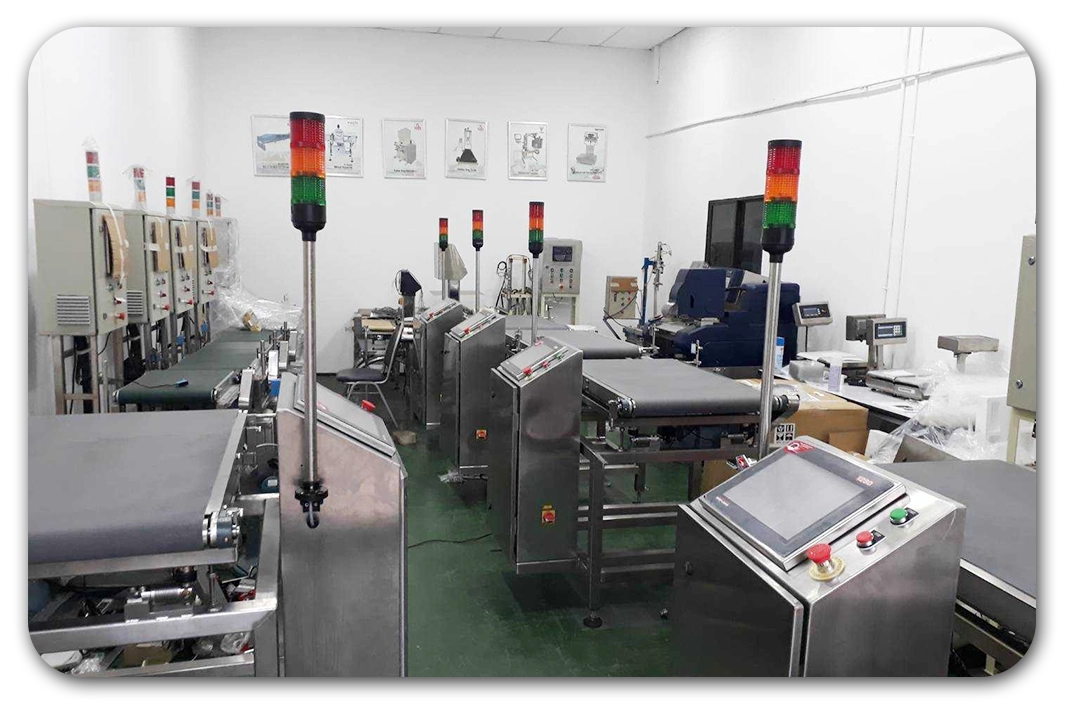

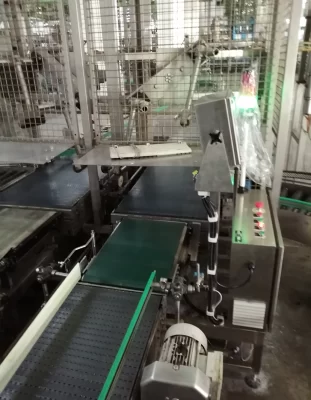

Check weight

Suitable for product weight inspection in continuous production line

Specification

- Capacity: 5-50 kg

- Readability: 0.01 kg

- Power source: 220 VAC, 50/60 Hz

- Operating Temperature: -10 to 40 °C

- Indicator 920i from America

- Conveyor speed: able to adjust 10-60 m. /minute

- Speed: 40 pcs/minute (depend on product)

- Able to save 100 lists of production formula

- Weighing by 1 load cell

- Reject System: Sweep arm, Blow off, Pusher, Stop Conveyor, etc.

- Data display: able to save …

- Total amount of products which pass the machine

- Weight of total products which pass the machine

- Total amount of product whose weight is lower

- Total amount of product whose weight is higher

- Operation control: 3 colored tower lamp

- Yellow: lower

- Green: Pass

- Red: Higher

Contact us/Get a quote

Call us

Telephone : 034-397-682-5 – 101, 110, 114

Phone : 087 041 0666 Phone : 086 366 7846

Email

sales@thaiscale.co.th

Add Line